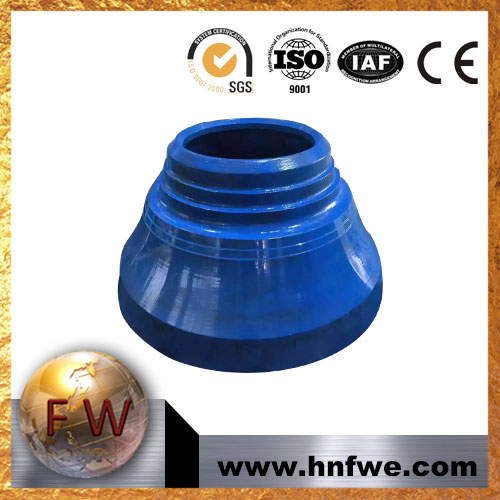

1. Oversupply When the feeding material is too much, the broken cavity will be full, which will bring the crusher a great pressure, and finally make the cone break overload operation. For a long time, ...

-

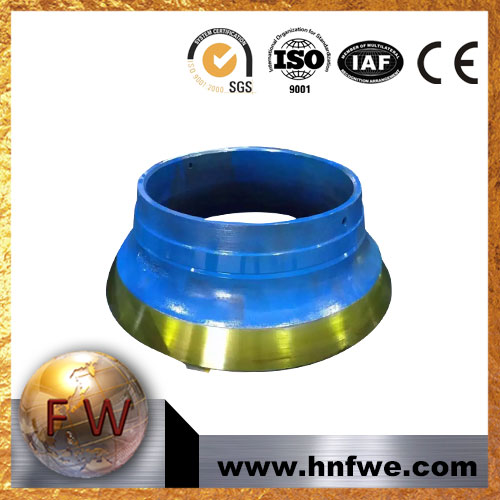

Fracture causes of Cone Crusher spindle

-

Key points of regular maintenance for impact crusher

1.The running point of the machine is stable. When the vibration of the machine increases suddenly, the reason should be eliminated by stopping immediately; 2.under normal conditions, the temperature r...

-

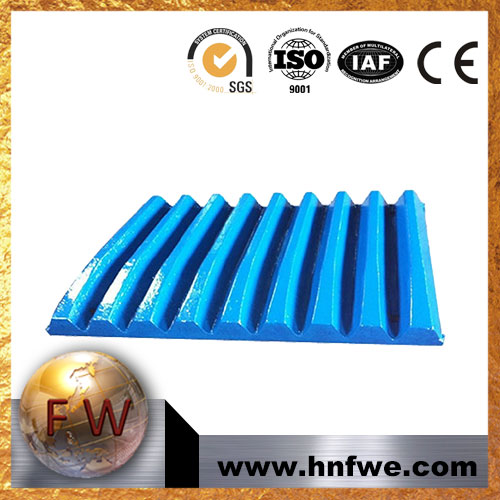

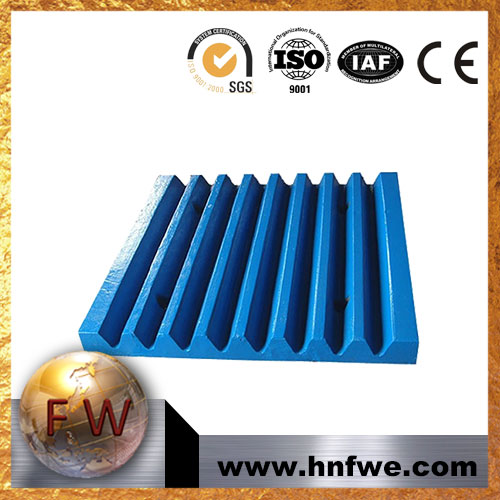

Factors influencing wear of mandibular broken plate

1. Hardness of material The hardness of the material has an important effect on the wear of the jaw plate. Under the same conditions, the materials with high hardness are easier to press into the surfa...

-

Lubrication of jaw crusher

Jaw crusher connecting rod bearings, eccentric shaft bearings, thrust plate elbow head lubricating oil. The 70 # mechanical oil is more suitable in summer. Mechanical oil No. 40 can be used in winter. ...

-

Jaw crusher preparation

Preparation before driving 1. Check whether the main parts are intact, whether the fastening bolts or other connectors are loose or not, and whether the safety devices are complete; 2, check feeding eq...

Twitter

Twitter Facebook

Facebook LinkedIn

LinkedIn