Hammer crusher is a high-speed rotary crushing machine. In order to ensure its normal operation, operators must strictly follow the procedures, and the maintenance of equipment. (1)before starting and ...

-

Operation and maintenance of hammer crusher

-

Malfunction and troubleshooting of hammer crusher

1. Bearing overheating Reason: insufficient grease; excessive grease; grease dirty deterioration; bearing damage. Elimination method: add proper amount of grease; the internal grease of bearing should ...

-

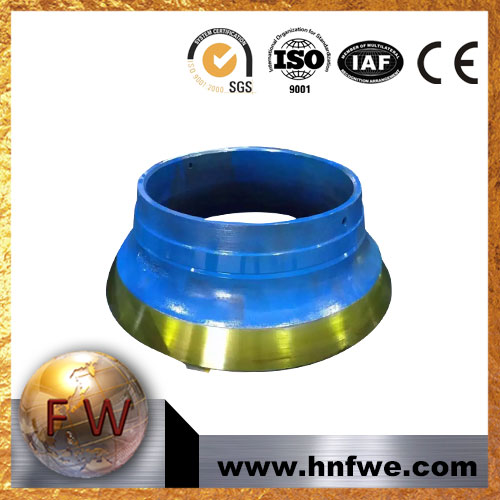

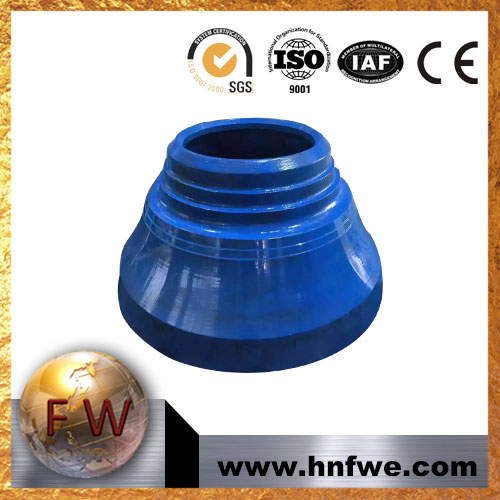

Structural Design and advantages of PE900x1200 jaw Crusher

1. Frame design and advantages The PE900x1200 jaw crusher adopts welding frame structure design and high quality steel plate to make up for the defects of casting. Its advantages can make the equipment...

-

Performance difference between jaw crusher and counter crush

The jaw crusher : deep crushing chamber and no dead zone, which improves the feed capacity and output, its crushing ratio is large, the product size is uniform, the cushion type discharging port adjust...

-

Maintenance of Roller Crusher

1, bearing crusher bearing bear the full load of the machine, so good lubrication has a great relationship with the life of the bearing. It directly affects the service life and operation rate of the m...

Twitter

Twitter Facebook

Facebook LinkedIn

LinkedIn